Our products

Compact design | Smart control | Perfect mixing result

Low pressure casting machines

We at Keymix Systems GmbH offer innovative, unique customized solutions for the industrial processing of reactive plastics, such as polyurethane, epoxy resins, silicones, polyamides and adhesives.

Mini-Mix Hot

- Probably the most compact hot molding system on the market

- Highest precision in temperature control – mixing ratios and ejections

- Perfectly suited for laboratory, pilot plant and small batch productions

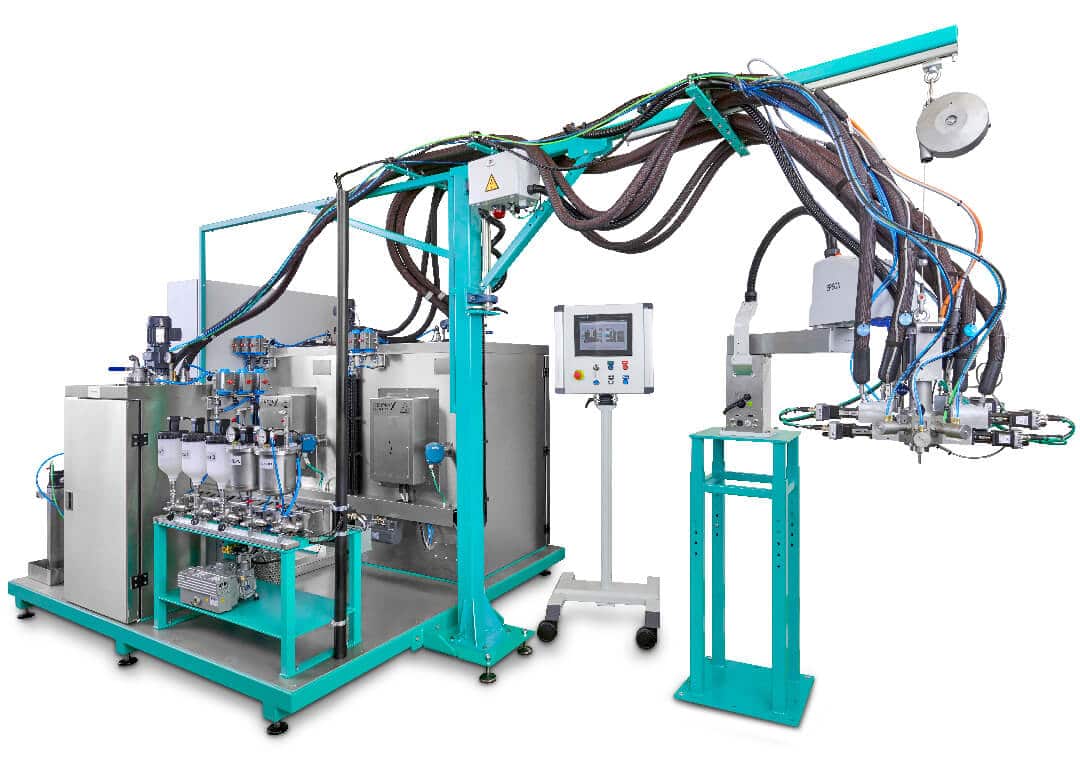

Hot Casting Machine KMH Series

- The perfect multi-component hot casting system for your series production

- Highest precision in temperature control – mixing ratios and ejections

- Perfectly suited for available low to medium viscosity PUR/polyamide systems

Stand-alone casting modules

- Ideal for flexible expansion of your hot or cold casting machine

- Easy connection to your existing system via plug & play solution

- For the preparation of additional, or alternative components

Mini-Mix Cold

- The compact cold casting machine for epoxy, silicone, adhesives and PUR systems

- High-precision control of mixing ratios and outputs

- Perfectly suited for laboratory, pilot plant and small batch productions

Cold Casting Machine KMC Series

- The flexible cold casting system for your production

- High-precision control of mixing ratios and outputs

- For cold applied polyurethane, epoxy, silicone and adhesive systems.

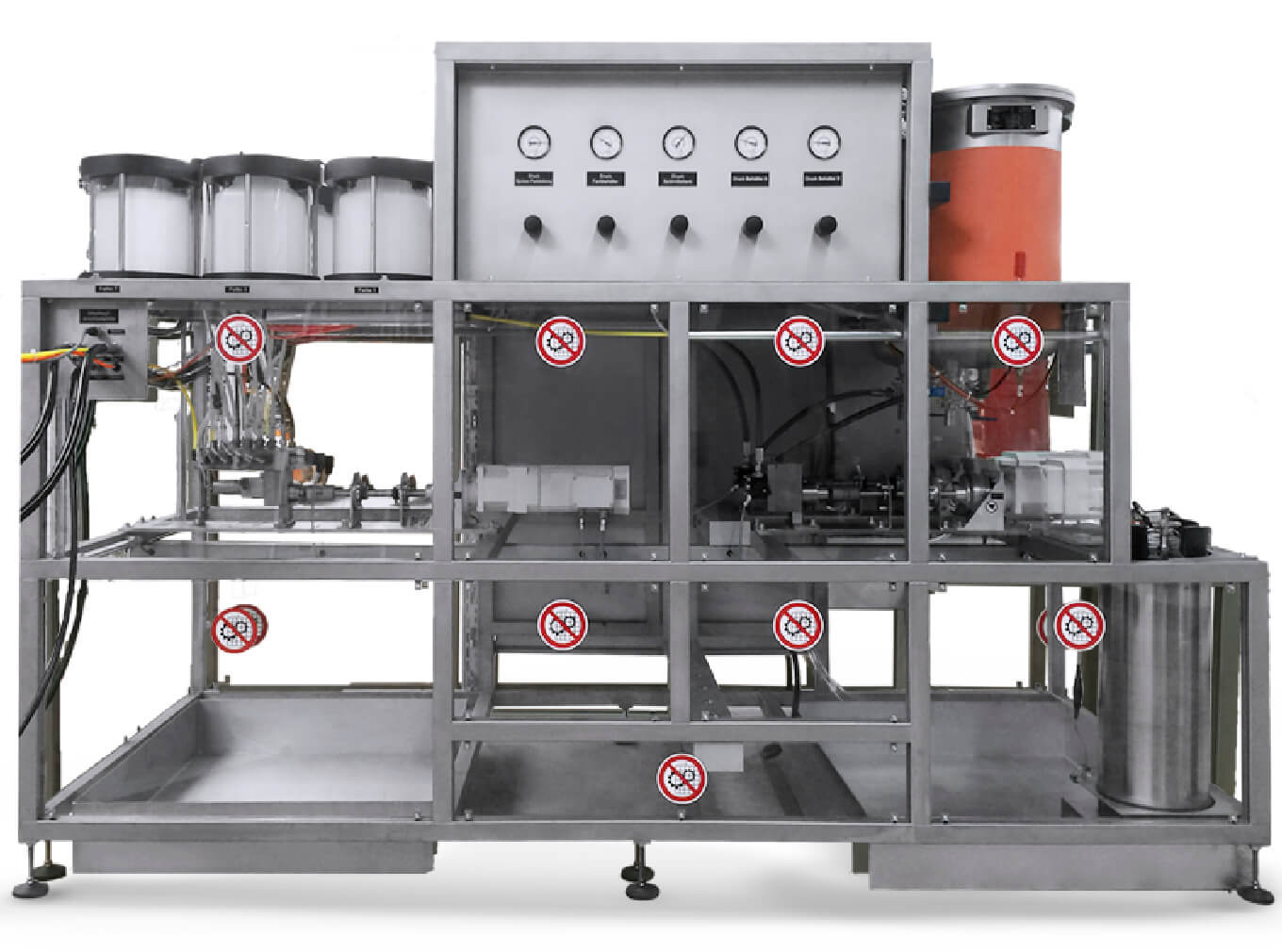

TPU Production Line KMT Series

- Semi-automatic production line for the manufacture of TPU sheets

- Consisting of: Dewatering station | MDI station | Stirring furnace | Crosslinker station | Stirring station | Plate furnace

- Individually configurable modules

TIMING | RELIABILITY | OUTPUT

Automation – A synergy of technology

We know what matters when you want to automate your production. Scheduled output with low manpower requirements, high and stable quality standards, and maximum reliability. All this and full control, from anywhere, at any time is offered by Keymix Systems automation.

Robocast

- Automatic production cell for the application of multi-component polyurethane, adhesive, sealant and foam materials as well as epoxy & silicones

- Automatic part detection by means of intelligent camera system

- IoT – Interface & ERP Integration

Conversion Without production losses | Cost efficiency | Latest technology

Modernization / Retrofit & Service of existing plants

Are some of your machines getting on in years, or not doing what they should? We can help your aging equipment get back on its feet. With state-of-the-art technology and a thorough retrofit of existing systems.

Retrofit & Service

- Refurbishment and modernization of aging equipment of own and third-party brands

- Ongoing service & maintenance of Keymix equipment

- Spare parts and operating supplies

The right composition | At the right time | In the right place

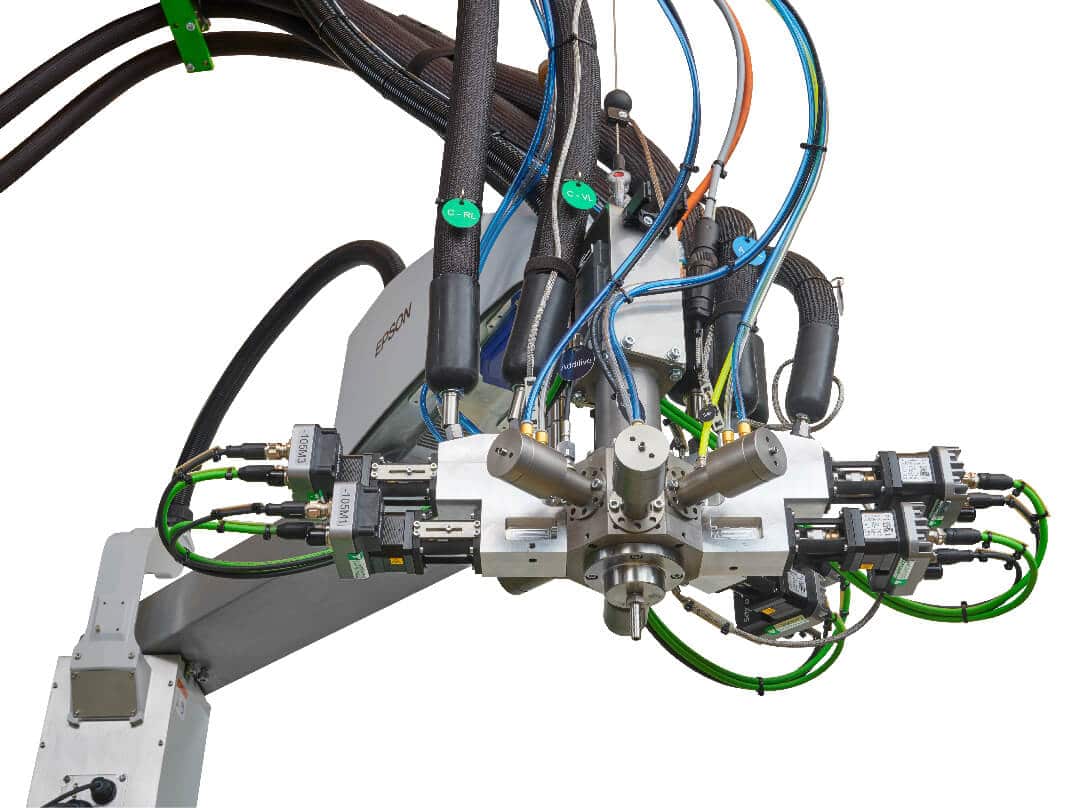

Mixing heads from Keymix – Quality decisive

The quality and reliability of products made of plastic, depends mainly on whether the right components, with the right temperature, at the right time in the ideal ratio are applied. This is exactly what mixing heads from Keymix are for.

Multicomponent mixing heads

- Low-pressure mixing head for a consistently high-quality mixing result

- Can be used in combination with robotics and/or swing boom

- Available in recirculating and pressure-regulating versions

Hand - mixing heads

- Ergonomically designed for excellent handling

- Available for static, rotostatic or dynamic mixing

- Mainly for solvent-free applications

- Individually adjustable

Know-how | Experience | Pioneering Spirit

Special solutions for your innovative production project

We speak from experience when it comes to developing new solutions for innovative processes and products. Let’s create something new together.

Centrifuge

- Centrifuge for the production of technical moldings

- Round heating chamber with integrated heating max. 150C°

- SPS control for automatic production process

Plate spinner

- Centrifuge for the production of film sheets and semi-finished products

- Lowest heat radiation due to high-quality insulating material

- Molds up to Ø 2000mm and width up to max. 1000mm

Energy efficiency | Practicability | Reliability

High quality stoves & heating tables

Our cooperation with strong partners, allow us to complement your production with high-quality furnaces and heating tables. In this way, we offer everything from a single source, for the least possible organizational effort on the part of our customers.

Material & Plate Furnaces

- Electric convection ovens up to

max. 150C° - For the tempering of materials, or for the tempering of freshly cast molded parts.

- For the tempering of materials, or for the tempering of freshly cast molded parts.

Heated pouring table

- Electrically heated casting table up to max. 130C°

- Made of solid aluminum in a sturdy sandwich construction. Surface anodized.

- Cover mounted on the table frame incl. Gas pressure damper for weight relief

Contact Us

Leave us a short message now, maybe together we will soon realize your next successful project.